Engineering

Our engineers are fixated on failure

When it comes to designing new furniture, there’s a beautiful battle between form and function. What may look stunning on paper, may not withstand the force of the real world. That’s where our engineers step in.

Although we have invested hundreds of thousands into in-house testing rigs, much of what is spotted comes from the experience of our engineers, who instinctively knows if a sweep of a chair’s back angle will compromise its structural integrity.

We make around ten prototypes, perfecting style, comfort, strength, stability and durability

Our refinement process is complex, beginning with a visual prototype to reflect on a piece’s overall aesthetic and proportions.

From this initial model, we scrutinise every curve, joint and intersection. Potential manufacturing or functionality issues are unearthed, and we consult a variety of body shapes and sizes to assess comfort and usability.

We use 3D printing technology to bring elements to life, before we create a final functional prototype to test performance and longevity.

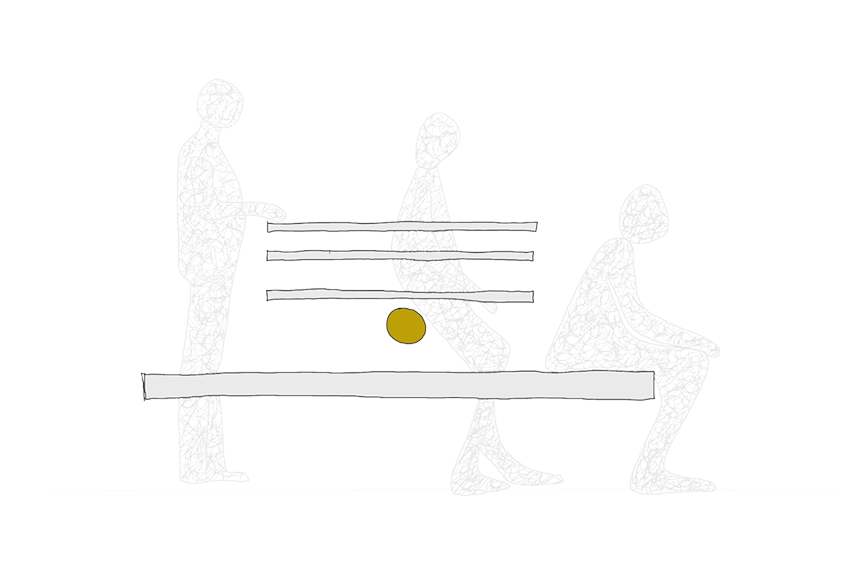

Product spotlight: CoLab

CoLab is designed in accordance with circular design principles, ensuring each component product in the system can be easily repaired. Exposed fixings promote ease of assembly, and simple on-site part replacement. Because no composite materials are used, any parts that do reach end-of-life can be recycled.